Energy Savings Realized Upon Completion of CST Project

Improvements were made to the mechanical systems at the Center for Science and Technology (CST) in 2021 and 2022. The multi-phase plan started in 2019 and is now complete. The project involved adding an energy recovery loop to the laboratory exhaust and reconfiguring the chillers to operate in heat recovery mode. These upgrades have resulted in a 25% reduction in steam use in 2023 and an annual emissions reduction of over 500 metric tons of carbon dioxide equivalent (MTCO2e).

The heat recovery chillers pull heat from the campus chilled water loop and heat the building’s dehumidification coils. At the same time, they reduce the chilled water load on the campus loop. This upgrade has reduced chilled water usage by over 67,000 ton-hours. This system, along with the lab exhaust energy recovery loop, helps to reduce steam and chilled water consumption, putting fewer demands on the district steam system and reducing campus greenhouse gas emissions.

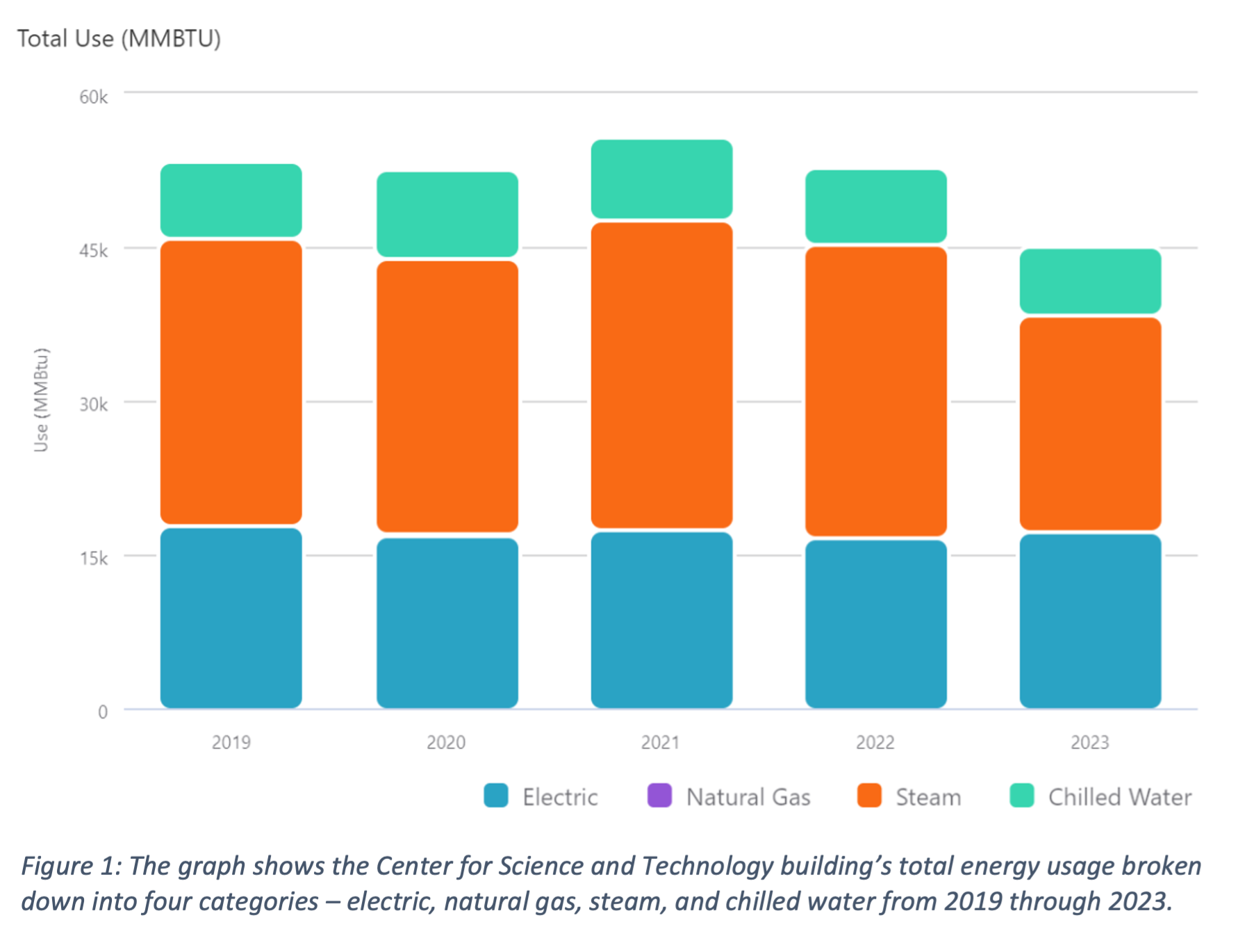

The biggest source of greenhouse gas emissions at Syracuse University is burning natural gas to create steam. Steam is used to heat University buildings and power a turbine chiller, which provides chilled water to cool buildings. Reducing steam-chilled water use at the buildings is a great way to reduce natural gas consumption and related emissions. This project is an example of energy efficiency strategies Sustainability Management is using to meet the 2032 carbon neutrality goal. The graph below shows the notable reduction in total energy use (MMBtu) and steam usage from 2022 to 2023.

“Instead of thinking of excess building heat as something that we needed to remove, we thought of heat as a resource that we needed to recover and reuse,” says Jason Plumpton, assistant director of engineering, utilities and sustainability. “We were able to make some minor adjustments to how we arranged the building mechanical systems to take advantage of this resource. This project was a great example of how we can incorporate sustainability into capital improvement projects.”

The Center for Science and Technology was completed in 1989. Over three decades later, the mechanical systems needed an update to support modern research. This project presented a great opportunity for Sustainability Management to align the need for an update with building decarbonization. Open labs were designed with efficiency in mind, allowing for shared use of equipment such as energy-intensive fume hoods. This design prevents hoods from going unused, and the installation of high-performance fume hoods further cuts down on energy use. Installing an energy recovery loop and reconfiguring the chillers to operate in heat recovery mode harnesses energy that would otherwise have been exhausted and gone unused. This project improved both capabilities and efficiency of the entire building.

Energy improvements in laboratory buildings are a major focus. A benchmarking study completed in 2023 confirmed that laboratory buildings that use a lot of outdoor air are the largest energy-consuming facilities on campus. Sustainability Management is focused on reducing energy usage in CST and other energy-intensive buildings to have a more meaningful impact on emission reductions and reduce utility costs.